Original equipment manufacturers (OEMs) have relied on Rudy’s Machine for precision machined parts for more than 50 years. In this time, our steady growth can be attributed to our ability to exceed expectations with superior products and services. This has allowed us to develop many long-standing relationships with OEMs and suppliers alike.

Original equipment manufacturers (OEMs) have relied on Rudy’s Machine for precision machined parts for more than 50 years. In this time, our steady growth can be attributed to our ability to exceed expectations with superior products and services. This has allowed us to develop many long-standing relationships with OEMs and suppliers alike.

Rudy’s Machine, one of the three manufacturing locations that comprise The Duny Group, began as a local tool and die shop in 1967. The skilled machinists at Rudy’s Machine regularly fabricate high-quality, custom machined parts for customers in a diverse range of industries.

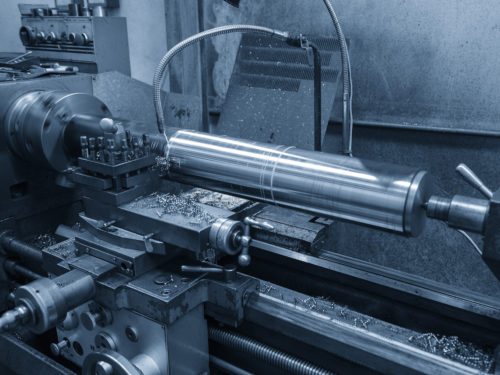

Manual Machining Capabilities

Rudy’s Machine offers manual machining services for customers across industries. While manual machining is ultimately less precise than CNC machining, it bears a lower cost and a significantly shorter set up time. Manual machining is a cost-effective option for proof-of-concept parts, part repair, rapid prototyping, replacement parts, and small production runs. In specific cases, manual production may also suit higher-volume production as well.

Our machinists can handle a variety of complex manual machining tasks, including:

- Boring

- Honing

- Internal broaching

- Milling

- Turning

- Blind hole keyway cutting

Our equipment portfolio also includes conventional lathes, horizontal mills, and vertical mills, enabling us to conduct a wide range of manual machining, large and small volume jobs, and repair operations.

Industries Served

At Rudy’s Machine, we’ve developed and nurtured many long-term business partnerships since our inception. Our current client list includes OEMs and Tier 2 & Tier 3 suppliers in sectors such as:

- Food and beverage

- Healthcare

- Hydraulics

- Industrial machinery

- Material handling

- Steelmaking

We also work with customers in a variety of other sectors and are open to opportunities and partnerships within new industries as well. Our versatile machining capabilities enable us to meet a variety of complex demands. We can typically achieve tolerances within 0.001 inches.

Our team also works with a myriad of material types. Though we are open to working with nearly any material, here are some of the most common:

- Aluminum

- Brass

- Bronze

- Carbon steel

- Hardened metals

- Plastics

- Stainless steel

- Tool steel

Contact Rudy’s Machine for Your Manual Machining Needs

While we most commonly apply our manual machining capabilities to repairs, the team at Rudy’s Machine can also provide manual machining as a cost-effective method for producing prototypes and other small-volume projects. We prioritize quality in everything we do, as evidenced by our ISO9001:2015 certification.

To see how our manual machining services will benefit your project, please contact us or request a quote today.